hindsight

Well-known member

As encouraged in another thread, I'll start posting some (largely historic now) detail on the recent bit of work that I did to my Bimota DB2SR. Most of this content I had already written and posted on the Bimota forum, but I'll review/update and repost some of it here, as others may find it interesting, and it may spark off some interesting conversations.

I've had several carbie 900SS's in the past, and back in 2018 or so, I was looking at a couple of Superlight's (well, who doesn't fancy a superlight, really?). Then, after half a bottle of wine one evening (well, it was probably nearer a full bottle, if I were to be honest), I figured that the DB2 was really the ultimate "Superlight" type machine, and the DB2 was certainly something that I'd lusted after for some time.

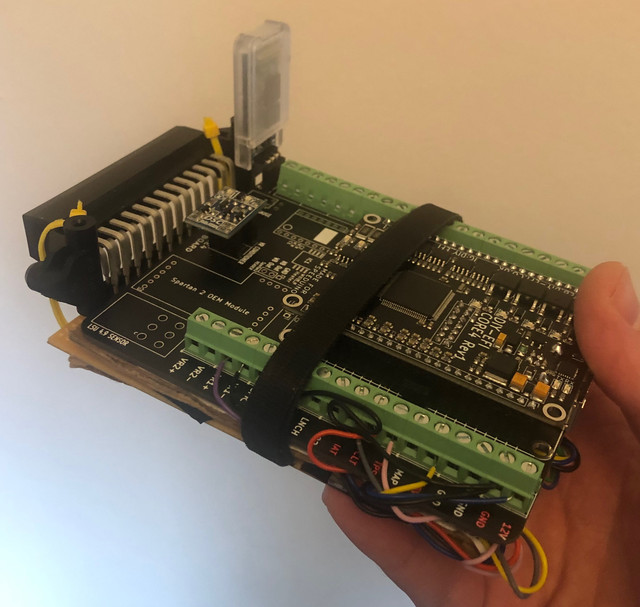

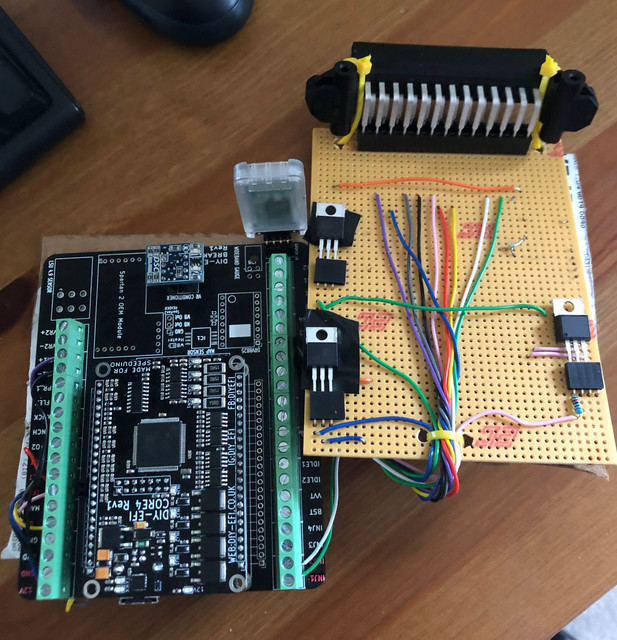

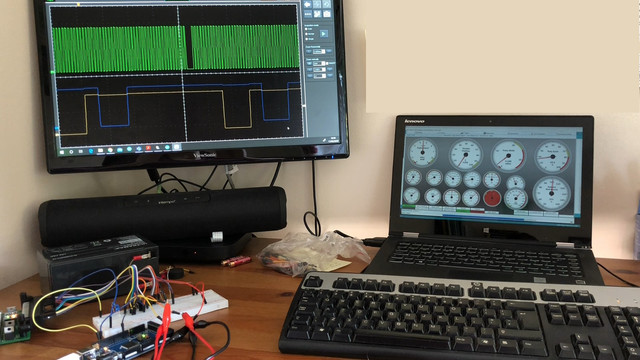

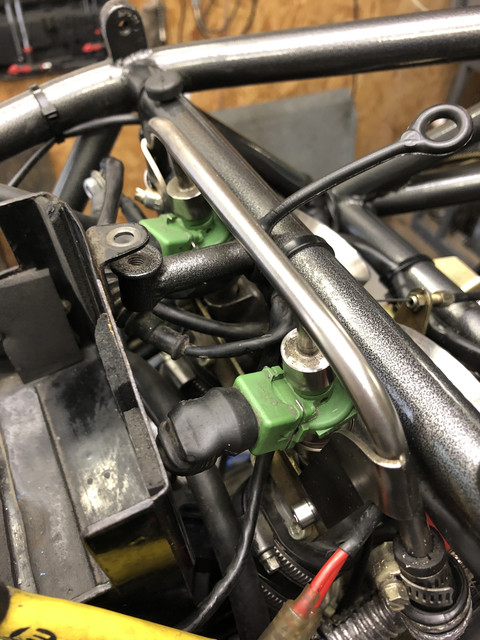

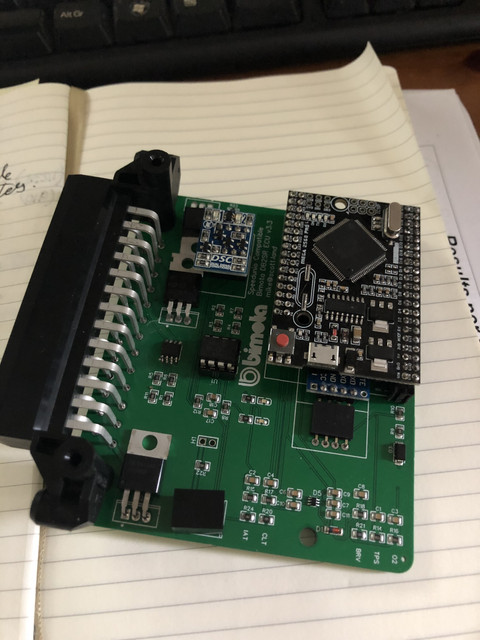

A few months later, and I'd purchased a DB2 from a nice fella in Wales (Hi Ralph, I suspect you'll stumble across this thread at some point). In fact - not just a normal DB2, but a DB2SR - which is the super-rare fuel injected version (most DB2's are carbie, but if the DB2 isn't rare enough as it is, a small handful of them had a custom FI system fitted at factory) in a lovely tricolore paint scheme.

In 2019 I took it on a lap of Scotland with some friends, and it was an absolute joy to ride. It weighs about as much as a well loaded cheese sandwich, and handles beautifully. I also had my 2015 Triumph Tiger 800 with me on that trip (a friend was riding it), and we swapped about - it was interesting that the ageing DB2 could still outperform the modern bike on nearly every parameter.

Later in 2019, in a fit of stupidity, I very nearly sold this bike - I'd advertised it, and even had contact from several people who were interested in purchasing, even internationally. To be fair, the reason I was considering selling was to fund the purchase of an RC45, but in a conversation that I still can't quite believe - SWMBO convinced me to keep the Bimota. As it turned out, I also walked away from the RC45 in a separate unrelated decision, but that's off topic.

So the DB2SR was to stay. Over the winter (November 2019) I lined up a service - nothing particularly special, just a set of belts (from Exige, thanks Stu), oil, clearances - the usual stuff. It doesn't get run hard, and doesn't get a lot of miles, so I wasn't planning on doing a lot of work on it, but it didn't exactly work out like that...

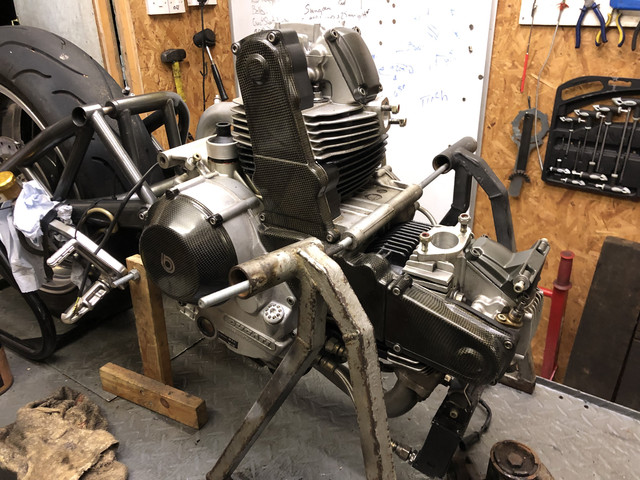

After stripping the bodywork off, and starting the service, I figured I would just pop the horizontal head off, just to check whether it still had the original bore size. As I measured the 92mm bore (904cc), a glimmer of an idea started to emerge, which soon escalated into what probably is my worst (best?) example of bike project scope creep so far..

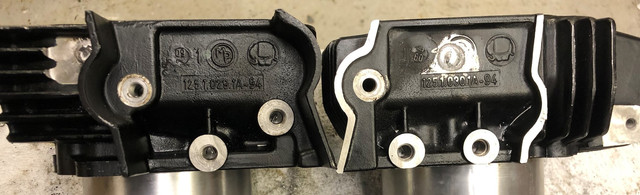

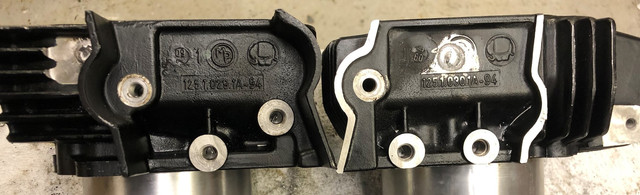

So the initial plan was to carry out a ST2/944 barrel/piston upgrade. I took a set of 94mm ST2 (water cooled) barrels and arranged for the necessary engineering work to convert them appropriately to be oil/aircooled. Essentially the trick here is to drill through the jacket into the coolant gallery, then weld up the hole in the jacket. The flanges on the barrels (previous used for coolant on the ST2) are then changed for the 900ss oil flanges, and the oil will then flood the jacket, and as a benefit it should giving greater cooling capability than the standard 900ss barrels which seem to use galleries for cooling, rather than a fully flooded jacket.

As I have no welding skills, the welding job wasn't done by me - so I explained to a professional what was required, and the job was done very tidily indeed. My contribution was a dab of black hammerite, and the job is almost invisible, aside from the missing fins that you can see on the left-hand barrel that was necessary to be machined to gain access. Virtually none of this is visible once the bike is back together though.

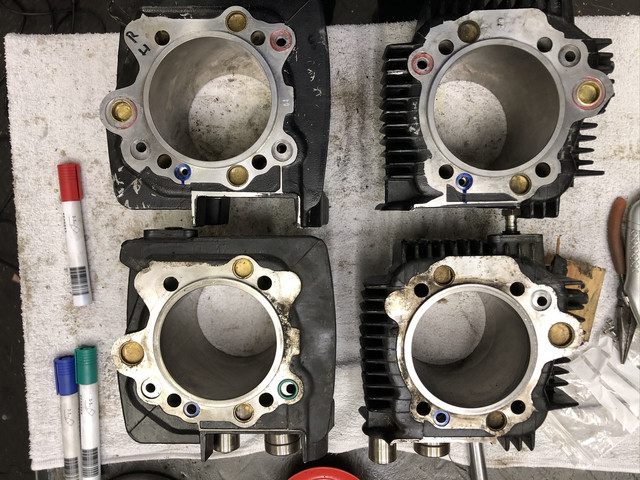

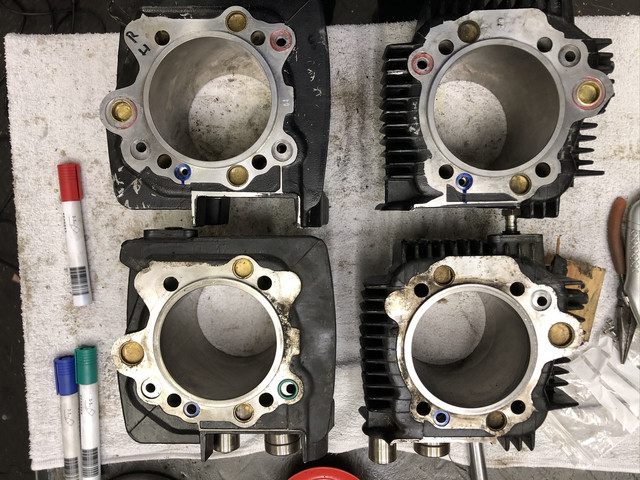

There's also a couple of holes in the top of the barrels that need to be blocked off with core plugs. In the below pic - the top pair of barrels are ST2, with blue and red markings of the changes that were midway through being made, and the bottom pair are the original DB2/900ss units.

Using the 94mm ST2 barrels is a nice way of doing a big bore conversation, because it leaves plenty of material on the cylinder wall, if I should choose to get them further bored to a larger capacity, and the additional oil cooling available to them should allow that (it also means that I've got the original 92mm/904cc barrels/pistons, should anything ever go wrong..). I could certainly go to 96mm/984cc in the future, and I suspect that 98mm/1068cc might be possible, but that would probably be pushing it a bit far...

The disadvantage of what I've done of course is that the pistons aren't particularly high-compression - but I could easily replace the pistons in the future, if that became a priority, and indeed, if I ever go to 96mm, then I'll need new pistons anyway...[self warning: potential for more scope creep...]

More to come in due course..

I've had several carbie 900SS's in the past, and back in 2018 or so, I was looking at a couple of Superlight's (well, who doesn't fancy a superlight, really?). Then, after half a bottle of wine one evening (well, it was probably nearer a full bottle, if I were to be honest), I figured that the DB2 was really the ultimate "Superlight" type machine, and the DB2 was certainly something that I'd lusted after for some time.

A few months later, and I'd purchased a DB2 from a nice fella in Wales (Hi Ralph, I suspect you'll stumble across this thread at some point). In fact - not just a normal DB2, but a DB2SR - which is the super-rare fuel injected version (most DB2's are carbie, but if the DB2 isn't rare enough as it is, a small handful of them had a custom FI system fitted at factory) in a lovely tricolore paint scheme.

In 2019 I took it on a lap of Scotland with some friends, and it was an absolute joy to ride. It weighs about as much as a well loaded cheese sandwich, and handles beautifully. I also had my 2015 Triumph Tiger 800 with me on that trip (a friend was riding it), and we swapped about - it was interesting that the ageing DB2 could still outperform the modern bike on nearly every parameter.

Later in 2019, in a fit of stupidity, I very nearly sold this bike - I'd advertised it, and even had contact from several people who were interested in purchasing, even internationally. To be fair, the reason I was considering selling was to fund the purchase of an RC45, but in a conversation that I still can't quite believe - SWMBO convinced me to keep the Bimota. As it turned out, I also walked away from the RC45 in a separate unrelated decision, but that's off topic.

So the DB2SR was to stay. Over the winter (November 2019) I lined up a service - nothing particularly special, just a set of belts (from Exige, thanks Stu), oil, clearances - the usual stuff. It doesn't get run hard, and doesn't get a lot of miles, so I wasn't planning on doing a lot of work on it, but it didn't exactly work out like that...

After stripping the bodywork off, and starting the service, I figured I would just pop the horizontal head off, just to check whether it still had the original bore size. As I measured the 92mm bore (904cc), a glimmer of an idea started to emerge, which soon escalated into what probably is my worst (best?) example of bike project scope creep so far..

So the initial plan was to carry out a ST2/944 barrel/piston upgrade. I took a set of 94mm ST2 (water cooled) barrels and arranged for the necessary engineering work to convert them appropriately to be oil/aircooled. Essentially the trick here is to drill through the jacket into the coolant gallery, then weld up the hole in the jacket. The flanges on the barrels (previous used for coolant on the ST2) are then changed for the 900ss oil flanges, and the oil will then flood the jacket, and as a benefit it should giving greater cooling capability than the standard 900ss barrels which seem to use galleries for cooling, rather than a fully flooded jacket.

As I have no welding skills, the welding job wasn't done by me - so I explained to a professional what was required, and the job was done very tidily indeed. My contribution was a dab of black hammerite, and the job is almost invisible, aside from the missing fins that you can see on the left-hand barrel that was necessary to be machined to gain access. Virtually none of this is visible once the bike is back together though.

There's also a couple of holes in the top of the barrels that need to be blocked off with core plugs. In the below pic - the top pair of barrels are ST2, with blue and red markings of the changes that were midway through being made, and the bottom pair are the original DB2/900ss units.

Using the 94mm ST2 barrels is a nice way of doing a big bore conversation, because it leaves plenty of material on the cylinder wall, if I should choose to get them further bored to a larger capacity, and the additional oil cooling available to them should allow that (it also means that I've got the original 92mm/904cc barrels/pistons, should anything ever go wrong..). I could certainly go to 96mm/984cc in the future, and I suspect that 98mm/1068cc might be possible, but that would probably be pushing it a bit far...

The disadvantage of what I've done of course is that the pistons aren't particularly high-compression - but I could easily replace the pistons in the future, if that became a priority, and indeed, if I ever go to 96mm, then I'll need new pistons anyway...[self warning: potential for more scope creep...]

More to come in due course..

Last edited: