I've decided to reproduce an article I originally posted on The Ducati Forum as it's a one that keeps getting referenced by others a bit when looking into installing a Lithium battery into an older Ducati that wasn't intended to be equiped with one originally, as it usually preceeded the technology.

So............I've got round to fitting the Mosfet regulator to the 1098R today. As I was a complete novice as to doing this conversion, I've decided to post this, in case it's useful to others doing the same.

Time -

So, here we go.........

Select your favourite 848, 1098, 1198.

Fairings and belly pan off.

Disconnect the battery negative cables.

Remove the ECU (2 bolts). I have read that people remove the battery box. I didn't need to.

Remove the regulator located behind the ECU (2 bolts)

My 2 regulator electrical connectors showed no signs of heat damage, so I could proceed. If yours do, rectify them. (no pun intended)

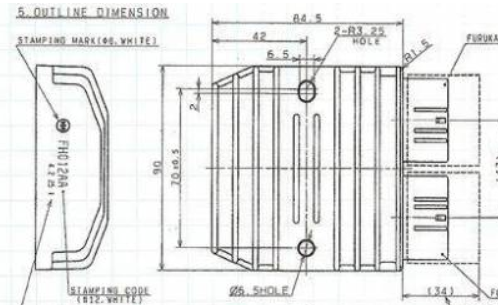

Before fitting the regulator to the Bikesprt Developments bracket I had to modify it to accept the Mosfet regulator. The bracket is manufactured for the original regulator, which has fixing centres of 80mm. The Mosfet unit has 70mm centres, so I had to drill an additional hole on the bracket.

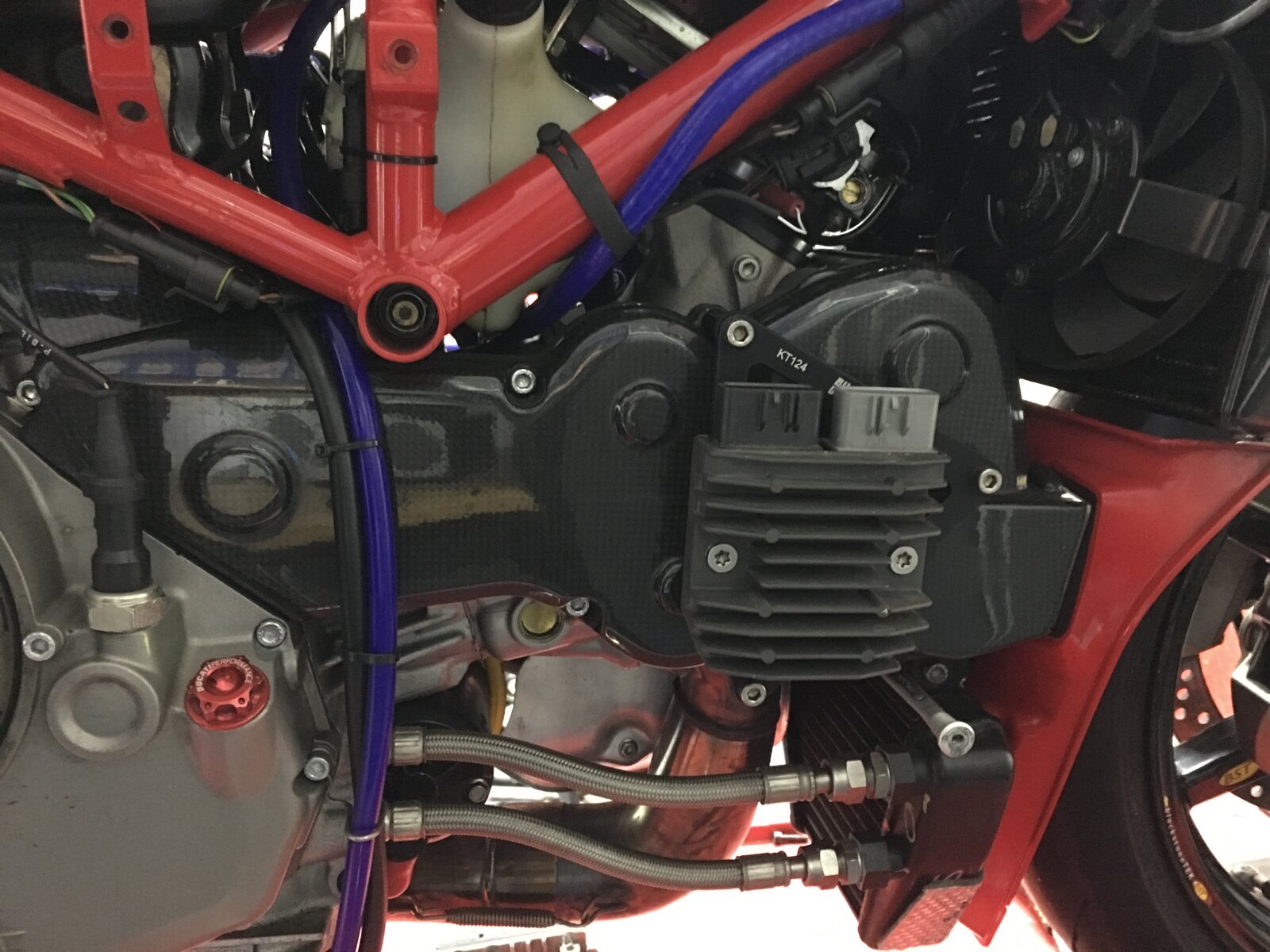

Fit the bracket and regulator the the RHS horizontal cam belt cover. Remove the 3 corresponding bolts from the cover and fit with the replacement bolts and spacers from the BS kit.

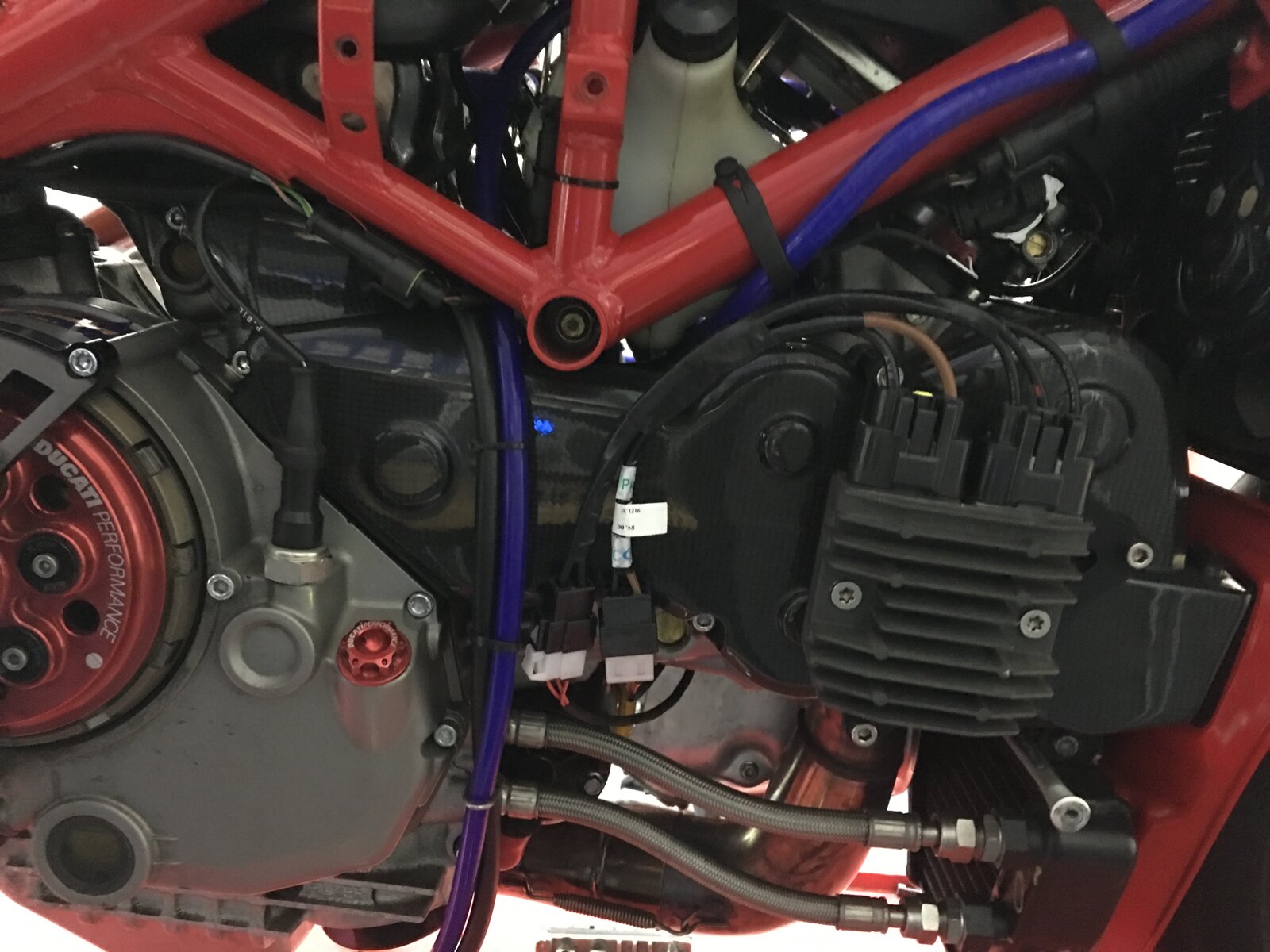

There was nothing in the kit which said where to route the cables to link with the loom on the LHS of the bike, but everything lent itself well to going under the horizontal cyl adjacent to the starter motor.

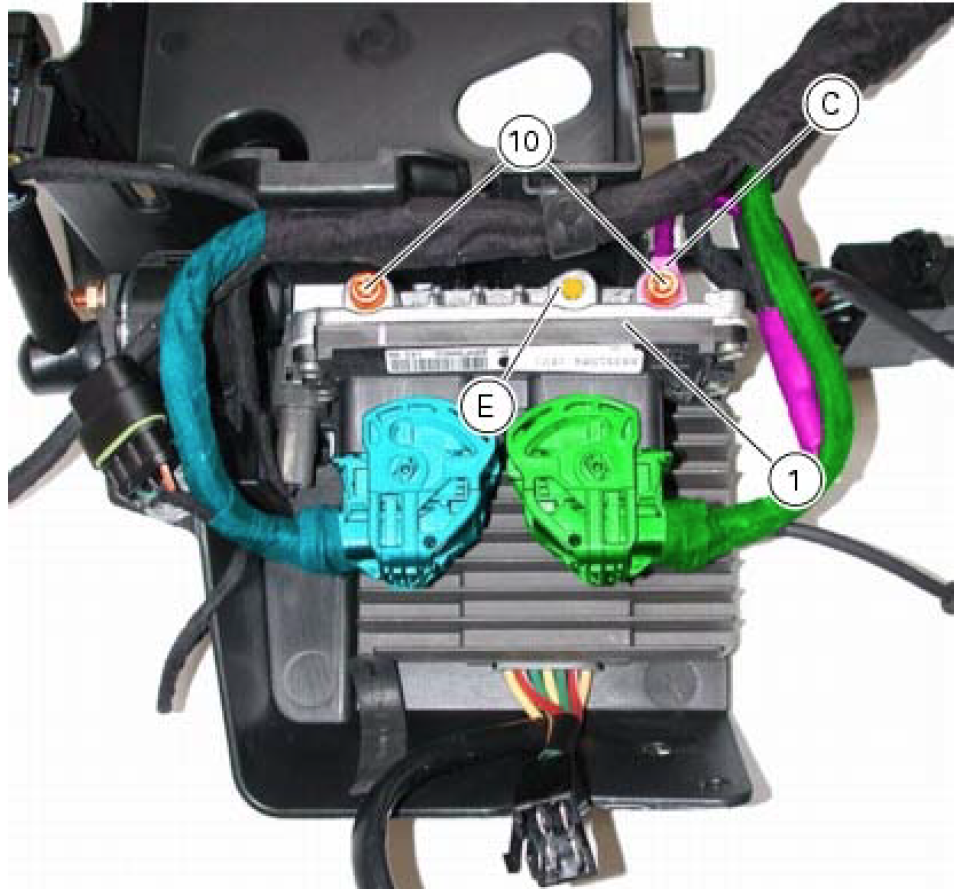

Difficult to tell in this pic, but I had to cut into the tape on the ECU loom to pull the original regulator connector backwards slightly to allow it to join the new wiring. Then taped the loom back up.

Refit the ECU. Ensure to connect the earth cable (C) to the RHS bolt of the ECU. The bike will not run without it, it's hidden behind the loom and easy to miss.

Cable tie everything back up.

Refit the bodywork to your favourite 848, 1098, 1198.

The regulator looks to be in a nice cool place once the bodywork is refitted.

Employ your original regulator as a paperweight.

So............I've got round to fitting the Mosfet regulator to the 1098R today. As I was a complete novice as to doing this conversion, I've decided to post this, in case it's useful to others doing the same.

Time -

- Approx 2 hours

- Mosfet regulator. I got this 2nd hand from a Ducati breaker for about £40. It's a part common with a load of bikes that Ducati make and fitted as std to the LiPo equipped Panigale R.

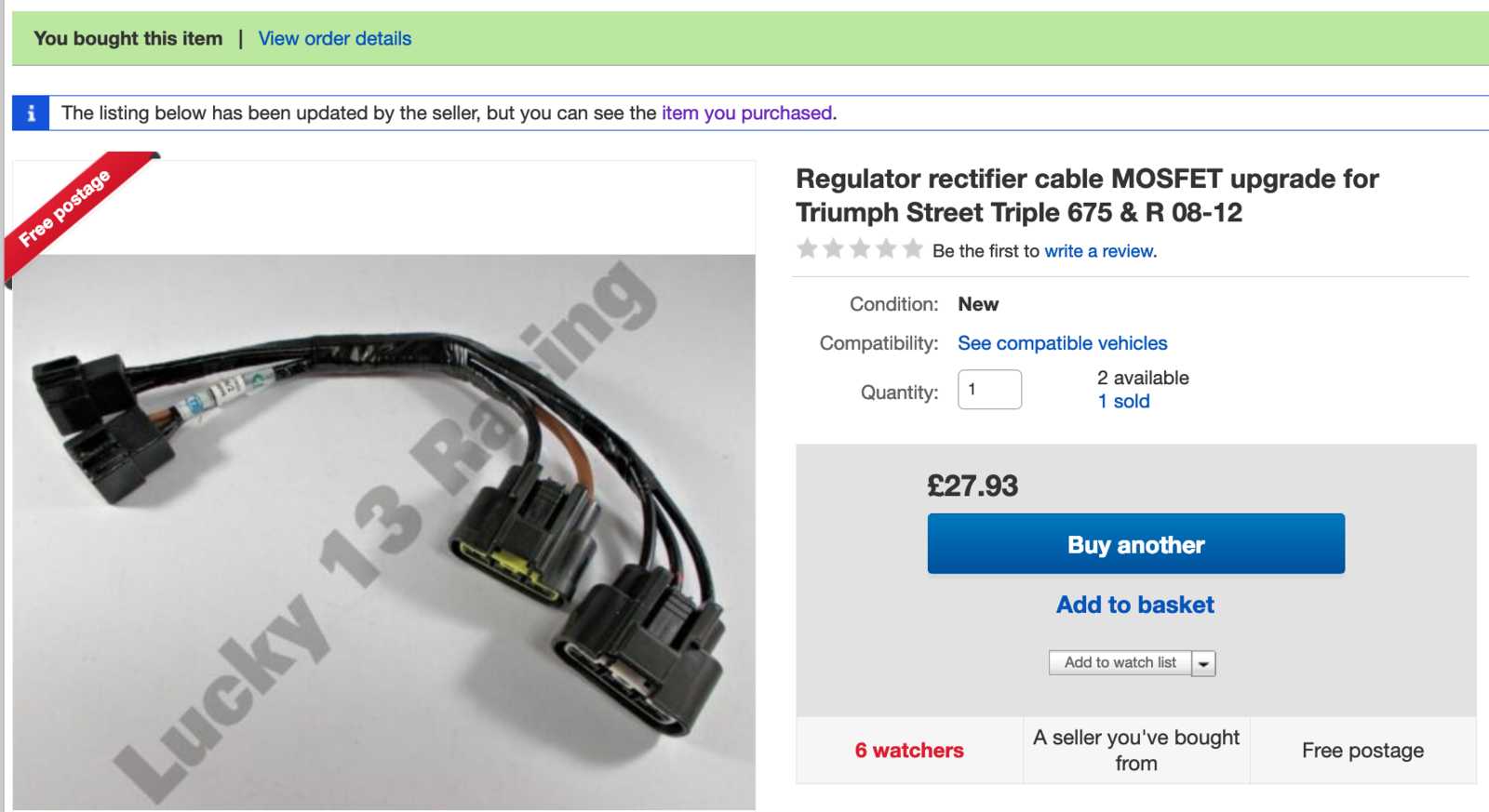

- Triumph conversion lead. About £28 from eBay, but I believe it's quite a bit cheaper from a dealer.

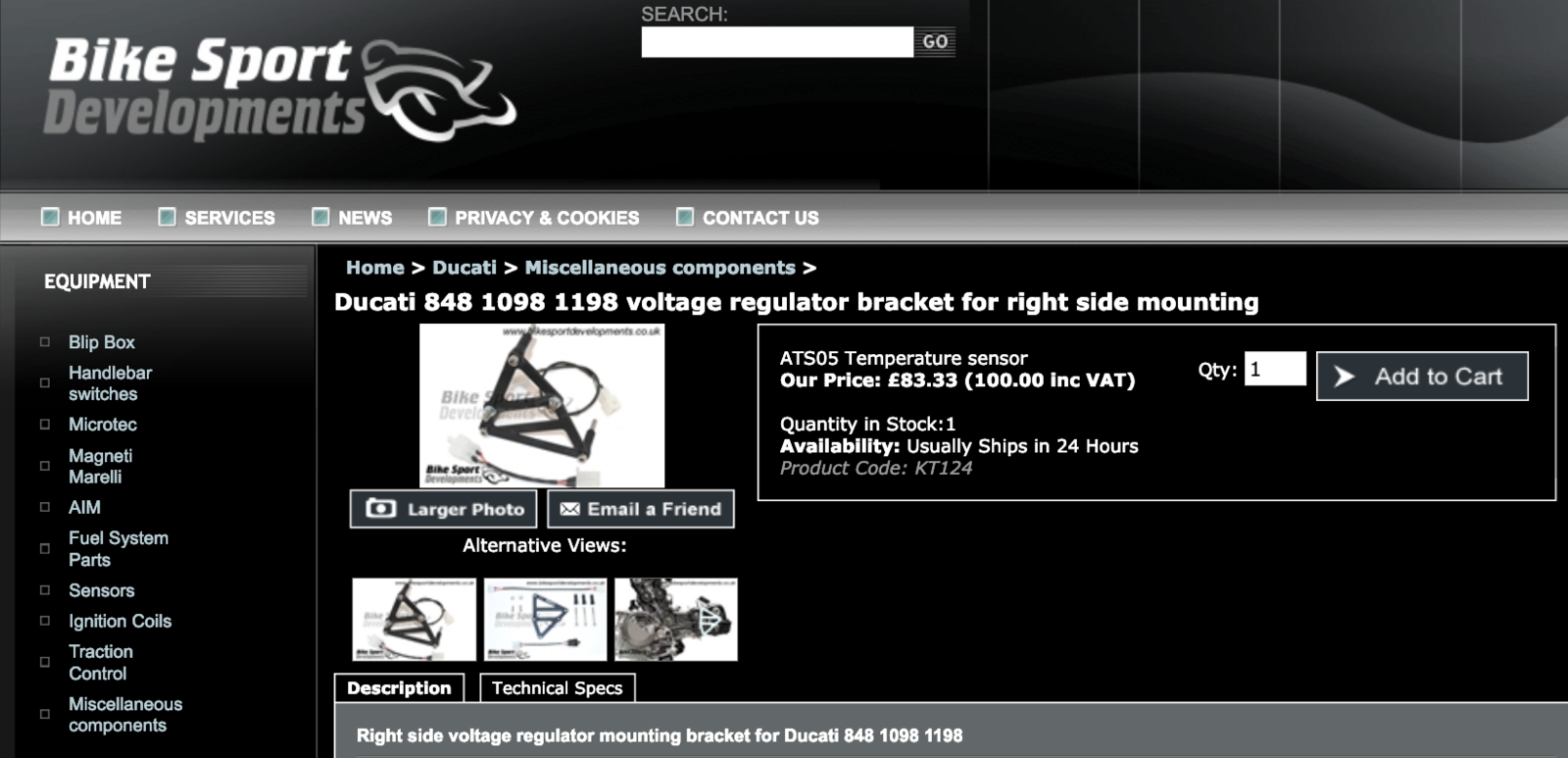

- Bikesport Developments RHS regulator conversion bracket, £100 (optional if you want to move the reg away from the exhaust). The original regulator is just above the exhaust and I imagine there's a lot of heat in the area. In fact, the heat shield on my bike has bubbled up as it's close to the 70mm system. This comes with extension leads and bolts / spacers.

So, here we go.........

Select your favourite 848, 1098, 1198.

Fairings and belly pan off.

Disconnect the battery negative cables.

Remove the ECU (2 bolts). I have read that people remove the battery box. I didn't need to.

Remove the regulator located behind the ECU (2 bolts)

My 2 regulator electrical connectors showed no signs of heat damage, so I could proceed. If yours do, rectify them. (no pun intended)

Before fitting the regulator to the Bikesprt Developments bracket I had to modify it to accept the Mosfet regulator. The bracket is manufactured for the original regulator, which has fixing centres of 80mm. The Mosfet unit has 70mm centres, so I had to drill an additional hole on the bracket.

Fit the bracket and regulator the the RHS horizontal cam belt cover. Remove the 3 corresponding bolts from the cover and fit with the replacement bolts and spacers from the BS kit.

There was nothing in the kit which said where to route the cables to link with the loom on the LHS of the bike, but everything lent itself well to going under the horizontal cyl adjacent to the starter motor.

Difficult to tell in this pic, but I had to cut into the tape on the ECU loom to pull the original regulator connector backwards slightly to allow it to join the new wiring. Then taped the loom back up.

Refit the ECU. Ensure to connect the earth cable (C) to the RHS bolt of the ECU. The bike will not run without it, it's hidden behind the loom and easy to miss.

Cable tie everything back up.

Refit the bodywork to your favourite 848, 1098, 1198.

The regulator looks to be in a nice cool place once the bodywork is refitted.

Employ your original regulator as a paperweight.

Last edited: